Weld Mesh vs Wire Mesh: Choosing the Right One Matters More Than You Think

Weld mesh and wire mesh solve different problems. When you match the mesh type to the job—not just the appearance—you get better performance, fewer issues, and smarter use of material.

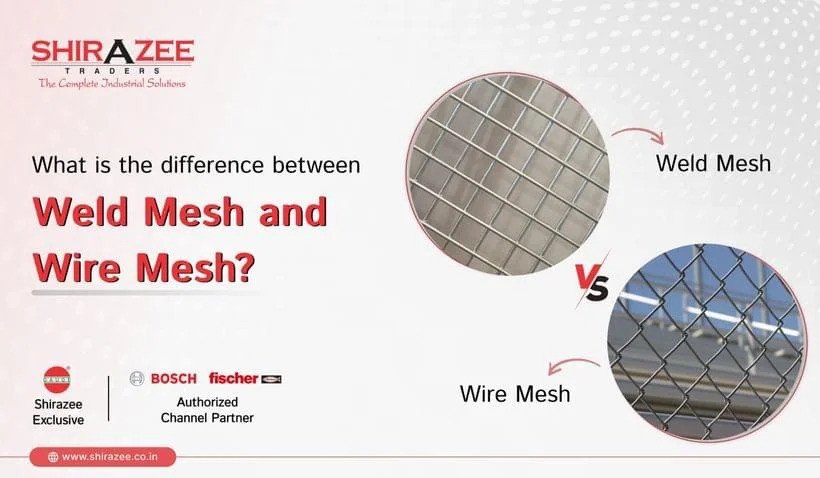

At first glance, weld mesh and wire mesh look almost identical. Both are made from metal wires. Both form a grid. Both are widely used across construction, industrial, and commercial projects.

But on-site, they behave very differently.

Many selection mistakes happen because buyers assume they are interchangeable. They’re not. And choosing the wrong one often leads to durability issues, rework, or unnecessary cost later.

Let’s break this down simply.

The Real Difference Starts With How They’re Made

Weld mesh is created by welding intersecting wires together at each joint. Every crossing point is permanently fused. Once formed, the grid stays rigid and fixed.

Wire mesh, on the other hand, is made by weaving wires over and under each other. There is no welding at the intersections, which keeps the mesh flexible and adjustable.

This single difference in manufacturing changes everything—from strength to application.

Strength vs Flexibility: What Actually Matters on Site

Weld mesh holds its shape under pressure. Because the joints are welded, the spacing does not shift when load is applied. This makes it suitable for applications where stability and uniformity are critical.

Wire mesh offers flexibility. The woven structure allows slight movement, which is useful in filtration, screening, and applications where shaping or fine control is needed.

Neither is “better” by default. The right choice depends on how the mesh will be used.

Where Each Type Is Commonly Used

Weld mesh is commonly chosen for:

- Construction reinforcement

- Fencing and security panels

- Cages and partitions

- Concrete and plaster support

Wire mesh is commonly used for:

- Filtration and sieving

- Ventilation and airflow control

- Insect screens

- Decorative or architectural elements

Problems usually arise when wire mesh is used where rigidity is required, or when weld mesh is used where flexibility is expected.

Why This Choice Affects Cost and Longevity

Using the wrong mesh doesn’t always fail immediately. Often, it shows up later as deformation, maintenance issues, or performance complaints.

Weld mesh tends to last longer in load-bearing or fixed installations. Wire mesh is easier to modify, replace, or adjust in precision-based applications.

Understanding this early helps avoid overengineering—or worse, under-specifying.

Want the Full Technical Comparison?

This article covers the practical difference. The complete breakdown includes:

- Strength comparison

- Durability factors

- Cost considerations

- Application-wise selection guide

Read the full detailed blog here:

Final Thought

Weld mesh and wire mesh solve different problems. When you match the mesh type to the job—not just the appearance—you get better performance, fewer issues, and smarter use of material.