Understanding the Role of Pipe Fittings in Oil, Gas, and Construction

Pipe fittings play a vital role in oil, gas, and construction by ensuring safety, efficiency, and adaptability. From elbows to socket weld flanges, discover how these small components keep massive systems running smoothly.

When you walk past a refinery, a construction site, or even a water treatment facility, it’s easy to notice the massive pipes running across structures. But what often goes unseen is the network of small yet essential components that make those systems safe and reliable pipe fittings. Without them, the oil and gas industry, as well as modern construction, would struggle to function smoothly.

In this article, we’ll break down the role of pipe fittings, why they matter, and how they keep some of the world’s most critical operations running without interruption.

Why Pipe Fittings Matter

Pipes are like highways for fluids and gases, but fittings are the junctions, bridges, and traffic lights that direct the flow. They ensure that pipes connect securely, change direction, and maintain pressure without leaks.

A few key reasons pipe fittings matter:

- Safety: Preventing leaks of oil, gas, or chemicals is not optional it’s life-saving.

- Efficiency: Well-designed fittings reduce energy loss and keep systems running at peak performance.

- Flexibility: They allow pipelines to adapt to space limitations, changes in direction, or different pipe sizes.

Whether it’s a gas processing plant, a skyscraper, or a drilling rig, fittings ensure that materials move where they’re needed, safely and reliably.

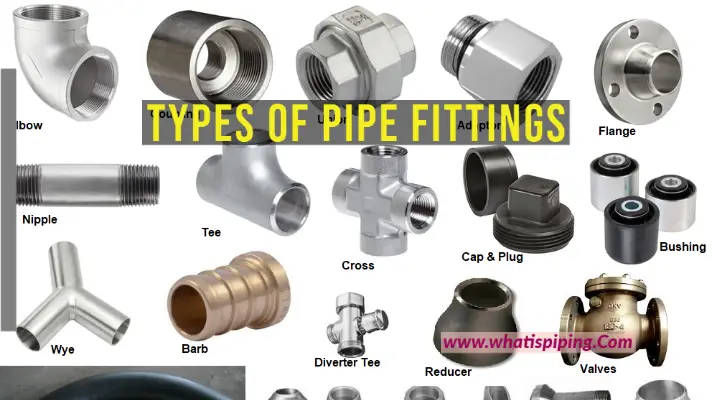

Common Types of Pipe Fittings

Pipe fittings come in many shapes and sizes, each designed for a specific job. Here are some of the most common ones you’ll find in oil, gas, and construction projects:

- Elbows – Used to change the direction of flow, usually at 45° or 90°.

- Tees – Allow a pipeline to split into two directions or merge from two into one.

- Reducers – Adjust the flow by connecting pipes of different sizes.

- Couplings and Unions – Connect two pieces of pipe together.

- Flanges – Provide easy assembly and disassembly of pipelines, especially useful in maintenance-heavy industries.

Each type plays a vital role in shaping the overall system.

The Role of Flanges in Heavy Industries

Among all fittings, flanges deserve special attention. They’re the connecting rings that make it easier to assemble and disassemble piping systems, especially where regular inspections are required. In oil and gas facilities, flanges are often used because maintenance crews need to open sections of pipelines without cutting into them.

One specific type, the socket weld flange, is widely used in smaller pipe sizes where a strong and leak-proof connection is critical. It combines the strength of a weld with the convenience of a flange, making it a popular choice in both high-pressure systems and construction projects.

Pipe Fittings in the Oil and Gas Industry

Oil and gas operations are some of the harshest environments for piping systems. High pressures, extreme temperatures, and corrosive fluids are all part of the daily challenge. Pipe fittings here are not just connectors; they are guardians of safety.

- High Pressure: Fittings are engineered to withstand pressures that could otherwise cause dangerous leaks or bursts.

- Corrosion Resistance: Materials like stainless steel or alloy fittings are used to handle crude oil, natural gas, or chemicals.

- Ease of Maintenance: Because downtime in oil and gas means massive financial loss, fittings like flanges allow for quick repair and replacement.

Pipe Fittings in Construction

On construction sites, the use of pipe fittings is just as critical, though the focus is slightly different. Here, fittings are about adaptability and ensuring that complex building systems like plumbing, fire safety, and HVAC work as intended.

For example:

- Plumbing systems use fittings to handle changes in direction and pressure.

- Fire sprinkler systems depend on reliable joints to activate without fail during emergencies.

- HVAC systems rely on fittings to distribute air efficiently through buildings.

In construction, fittings are all about making sure the invisible systems behind walls and ceilings keep people safe and comfortable.

Choosing the Right Pipe Fitting

Not all fittings are created equal. Choosing the right one depends on:

- Material – Steel, stainless steel, copper, or plastic depending on environment.

- Pressure Rating – Must handle the operating pressure of the system.

- Temperature – Needs to withstand heat or cold without losing integrity.

- Application – Industrial plants versus commercial buildings require different fitting standards.

A poor choice in fittings doesn’t just risk leaks—it can lead to costly downtime, safety hazards, and even environmental disasters.

Final Thoughts

Pipe fittings may not get the spotlight, but they’re the backbone of industries that keep the modern world moving. From keeping oil flowing in pipelines to ensuring safe drinking water in cities, their role is vital.

Whether it’s a refinery, a high-rise building, or an offshore rig, the right fitting be it an elbow, reducer, or a socket weld flange ensures safety, reliability, and efficiency.

Next time you see a giant network of pipes, remember: it’s the humble fittings that make the whole system possible.