The Science Behind Aluminium Powder Coating Durability

The Science Behind Aluminium Powder Coating Durability

In modern industrial and architectural applications, aluminium powder coating is recognized for its exceptional durability and long-lasting finish. Unlike traditional liquid paints, powder-coated aluminium forms a chemically bonded, resilient layer that resists scratches, fading, corrosion, and UV damage. This durability is a result of a carefully controlled process involving surface preparation, electrostatic powder application, and heat curing. Understanding these steps explains why powder-coated aluminium is the preferred choice for manufacturers, builders, and designers seeking a high-performance, low-maintenance solution.

Step 1: Meticulous Surface Preparation

Durability begins with surface preparation. Aluminium surfaces are first thoroughly cleaned to remove dirt, oils, and any oxidation. This cleaning ensures that the coating adheres uniformly and effectively. Following cleaning, a conversion coating is applied. This thin chemical layer, often phosphate-based, creates a microscopically etched surface that allows the powder to bond chemically rather than merely sitting on top of the metal. After this, the aluminium is dried, ensuring no moisture remains to interfere with adhesion or the curing process. This meticulous preparation ensures that the base metal is ready to receive a coating that will last for years.

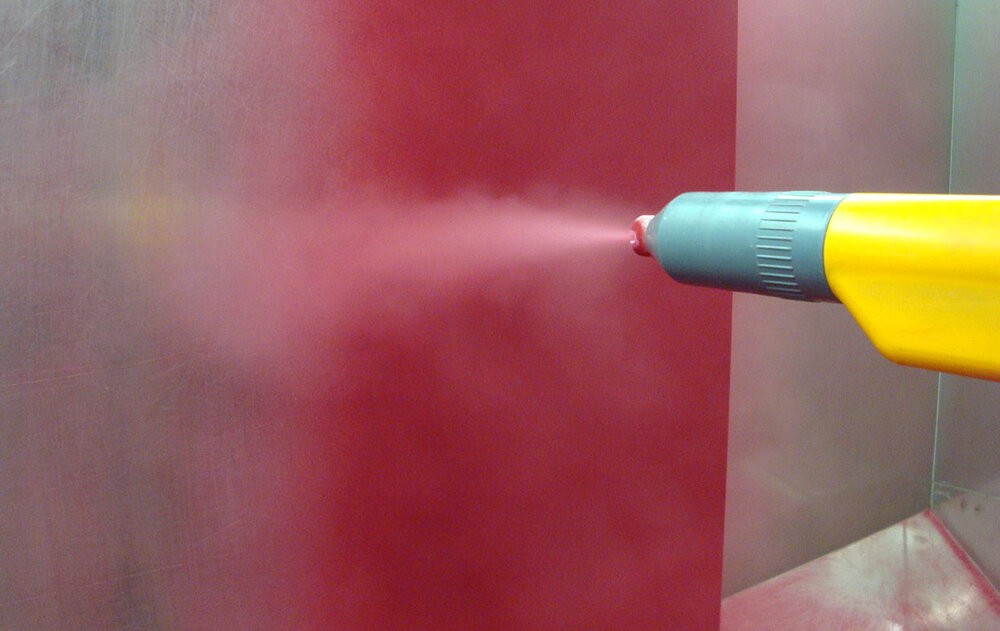

Step 2: Electrostatic Powder Application

The next step in achieving long-lasting durability is the application of the powder itself. Finely ground resin and pigment particles are electrostatically charged, giving them the ability to adhere uniformly to the grounded aluminium surface. This electrostatic attraction causes the powder to “wrap” around edges and contours, forming a complete and even coating layer. Unlike liquid paints, which can run or sag, powder particles remain in place, ensuring full coverage and eliminating weak spots that could compromise longevity. This step is crucial for producing a uniform, resilient layer that resists environmental and mechanical stresses.

Step 3: Heat Curing for Chemical Bonding

Once the powder is applied, the coated aluminium undergoes a heat-curing process. Typically heated between 150-200°C, the powder melts and flows to form a smooth film. For thermoset powders, the heat initiates a chemical reaction, creating cross-links between the resin molecules. This thermoset reaction produces a hard, chemically integrated surface that is significantly tougher than standard paints. The curing process ensures that the powder coating forms a permanent bond with the aluminium, transforming it into a durable, impact-resistant, and weatherproof finish.

Why Aluminium Powder Coating Is Exceptionally Durable

The durability of powder-coated aluminium stems from both chemical and physical properties. The cured layer forms a strong chemical bond with the underlying metal, making it highly resistant to peeling or chipping. The uniform, cross-linked film acts as an impenetrable barrier, protecting aluminium from moisture, UV radiation, pollutants, and even salt exposure. Furthermore, the baked-on coating is both harder and more flexible than conventional paint, allowing it to withstand impacts without cracking. This combination of toughness, adhesion, and weather resistance explains why aluminium powder coating outperforms other finishing methods.

Practical Benefits for Industry and Interiors

Beyond durability, aluminium powder coating offers several practical advantages. Its low-maintenance surface repels dirt and stains, requiring minimal cleaning over its lifespan. The wide range of available colors and finishes makes it versatile for both functional and decorative applications. Designers and manufacturers can rely on powder-coated aluminium for furniture, window frames, railings, kitchen panels, and industrial components, confident that the finish will remain attractive and resilient for decades. The process is also environmentally friendly, using no harmful solvents and producing minimal waste, aligning with sustainable manufacturing practices.

Conclusion

The science behind aluminium powder coating demonstrates why it is a superior finishing method for modern applications. By combining meticulous surface preparation, precise electrostatic application, and advanced heat curing, the process produces a durable, chemically bonded, and weather-resistant layer. This makes powder-coated aluminium a preferred choice for industries that demand both aesthetic appeal and long-lasting performance.

Companies like JM Aluminium exemplify excellence in this field. Known for precision engineering and advanced coating technology, JM Aluminium provides high-quality powder-coated aluminium solutions suitable for architectural, industrial, and interior applications. Their products reflect a commitment to consistency, durability, and design versatility, enabling builders and designers to achieve both functional and aesthetic goals. With years of expertise, JM Aluminium delivers finishes that resist wear, maintain color integrity, and meet stringent industry standards, making them a trusted partner for high-performance aluminium products.Whether used in commercial facades, high-end kitchens, furniture, or industrial machinery, powder-coated aluminium from reliable manufacturers ensures longevity, low maintenance, and a premium finish.