The Future of Automation: How Soft Robotic Technology Is Transforming Modern Industries

The Soft Robotic Finger is expected to become even more sophisticated, incorporating tactile sensing and real-time feedback.

Automation has entered a new era, driven by innovation that prioritizes adaptability, safety, and precision. Traditional rigid automation systems, while powerful, often struggle when interacting with delicate, irregular, or unpredictable objects. This challenge has paved the way for soft robotic technologies, which are rapidly redefining how industries approach handling, gripping, and manipulation tasks. At the heart of this transformation are advanced solutions developed by leaders such as Soft Robotics Inc, whose breakthroughs have influenced manufacturing, logistics, healthcare, and beyond.

Understanding Soft Robotics and Its Importance

Soft robotics is a field that focuses on creating machines using flexible, compliant materials rather than rigid metal components. These systems mimic biological structures, allowing them to bend, stretch, and adapt to their environment. This adaptability makes soft robots especially valuable in environments where precision and gentle handling are essential.

Unlike conventional automation, soft robotic systems are inherently safer for human collaboration. Their compliance reduces the risk of injury, enabling closer human-robot interaction on factory floors and in medical environments. As industries move toward collaborative automation, soft robotics is becoming a foundational technology rather than a niche innovation.

The Role of the Soft Robotic Finger in Precision Handling

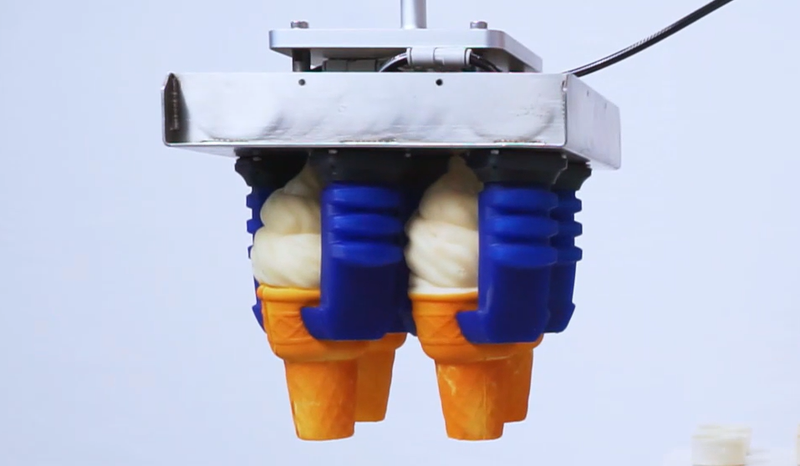

One of the most impactful components of modern soft robotic systems is the Soft Robotic Finger. Designed to replicate the natural movement and sensitivity of a human finger, this technology allows robots to grasp objects of varying shapes, sizes, and fragility without complex programming or mechanical adjustments.

A Soft Robotic Finger can conform around an object, distributing pressure evenly and minimizing damage. This capability is especially critical in industries such as food processing, where items like fruits, baked goods, and packaged products require careful handling. Similarly, in electronics manufacturing, these fingers can manipulate sensitive components without risking scratches or breakage.

Beyond manufacturing, the Soft Robotic Finger is also making waves in medical and research applications. From assisting in surgical tools to enabling advanced prosthetics, its ability to provide controlled, gentle interaction opens new possibilities for patient care and rehabilitation.

Industry Applications Driving Adoption

Soft robotic technologies are no longer experimental; they are actively reshaping multiple industries:

- Manufacturing and Assembly: Flexible gripping solutions allow for faster changeovers and reduced downtime, as robots can handle diverse products without retooling.

- Logistics and Warehousing: Automated picking systems benefit from soft grippers that can manage irregular packages efficiently.

- Food and Agriculture: Gentle handling reduces waste and improves hygiene standards.

- Healthcare: Soft robotic components enhance safety and precision in patient-facing applications.

Companies adopting these technologies often see improvements in productivity, product quality, and workplace safety. Solutions from innovators like Soft Robotics Inc have demonstrated that flexibility and reliability can coexist in industrial automation.

Innovation and Customization in Soft Gripping Solutions

Customization is a key advantage of soft robotic systems. Unlike rigid grippers that require precise alignment and programming, soft grippers adapt naturally. This adaptability reduces engineering complexity and speeds up deployment.

One notable example is SRT Soft Gripper, which focuses on delivering tailored soft gripping solutions for diverse industrial needs. By leveraging compliant materials and intelligent design, the company enables businesses to integrate automation without compromising on product integrity or operational efficiency. The emphasis on modularity and ease of integration ensures that even small and medium-sized enterprises can benefit from advanced robotics.

As industries evolve, the demand for customized automation solutions continues to grow. Soft robotic systems meet this demand by offering scalable, flexible, and cost-effective alternatives to traditional automation.

The Future Outlook of Soft Robotics

The future of soft robotics is closely tied to advancements in materials science, artificial intelligence, and sensor technology. As materials become more durable and responsive, soft robots will gain greater strength and longevity. Integration with AI will further enhance their ability to learn from interactions, improving accuracy and efficiency over time.

The Soft Robotic Finger is expected to become even more sophisticated, incorporating tactile sensing and real-time feedback. This evolution will allow robots to “feel” objects, adjusting grip strength dynamically and performing tasks that were once exclusive to human hands.In parallel, sustainability is becoming a critical consideration. Soft robotic systems often consume less energy and reduce material waste, aligning with global efforts toward greener manufacturing practices.

Conclusion

Soft robotics represents a fundamental shift in how automation interacts with the physical world. By prioritizing flexibility, safety, and adaptability, these technologies address long-standing limitations of traditional robotics. Innovations pioneered by Soft Robotics Inc have accelerated adoption across industries, proving that soft automation is not just feasible but essential for modern operations.

As companies seek competitive advantages through smarter automation, solutions like those offered by SRT Soft Gripper highlight the practical benefits of soft robotic design. With continued innovation, soft robotics will remain at the forefront of industrial transformation, enabling businesses to handle complexity with precision and care.