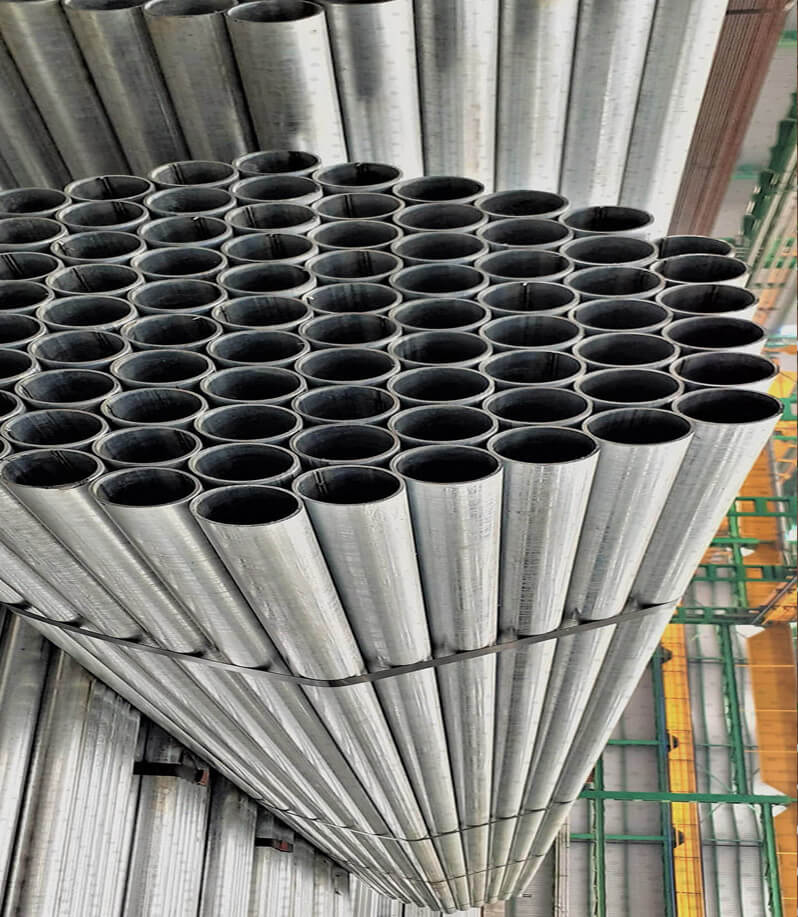

Stainless Steel 304 IRB Pipes Tubes-Strength, Precision, and Durability for Industrial Applications

Stainless Steel 304 IBR pipes and tubes stand out in the market due to their commendable attributes.

When it comes to reliable and high-performance piping solutions, Stainless Steel 304 IRB Pipes & Tubes offer the perfect combination of corrosion resistance, mechanical strength, and long service life. Widely used across various industries, these pipes and tubes are specifically engineered to meet the demands of high-pressure and high-temperature environments, while also delivering superior surface finish and dimensional accuracy.

In this article, we explore the features, benefits, and applications of SS 304 IRB pipes and tubes and why they are a preferred choice in critical industrial systems.

What Are Stainless Steel 304 IRB Pipes & Tubes?

IRB stands for Internal Ribbed, referring to a specific internal surface finish or design modification that enhances flow characteristics and pressure tolerance. Stainless Steel 304, an austenitic grade, is known for its excellent corrosion resistance, weldability, and mechanical properties.

When combined, 304 IRB Pipes & Tubes provide optimized internal surface design with the robustness of SS 304 material. These tubes are ideal for transporting fluids, gases, or chemicals with higher efficiency and minimal pressure loss.

Key Features of SS 304 IRB Pipes & Tubes

✅ Superior Corrosion Resistance

SS 304 offers excellent resistance to corrosion in a wide range of environments, including oxidizing acids, chloride-rich media, and high-humidity conditions. This ensures longevity and reduced maintenance.

✅ Enhanced Internal Surface (IRB Design)

The internal ribbed or smooth-finished design of IRB tubes helps reduce frictional losses and turbulence. This is particularly useful in high-flow systems and fluid transport applications.

✅ High Strength and Durability

With strong tensile and yield strength, SS 304 IRB pipes can withstand high pressure and thermal stress, making them ideal for both mechanical and structural applications.

✅ Excellent Fabrication and Weldability

SS 304 IRB pipes and tubes are easy to cut, weld, bend, and fabricate. This flexibility makes them suitable for custom system designs and complex industrial installations.

✅ Hygienic and Non-Toxic

Being non-reactive and easy to clean, 304 IRB tubes are suitable for hygienic applications in food processing, dairy, and pharmaceuticals.

Technical Specifications

- Material: Stainless Steel 304 / 304L

- Standards: ASTM A312, ASTM A269

- Type: Seamless / Welded / ERW

- Size Range: ½” NB to 12” NB or custom sizes

- Wall Thickness: Sch 5S to Sch 40S

- Finish: Pickled, Annealed, Polished (Mirror or Satin)

Applications of Stainless Steel 304 IRB Pipes & Tubes

Owing to their excellent corrosion resistance and smooth internal finish, SS 304 IRB pipes and tubes are used in:

- 🏭 Chemical and Petrochemical Plants

- ⚡ Power Generation

- 🚢 Marine & Offshore Equipment

- 🍶 Food & Beverage Processing Units

- 💊 Pharmaceutical and Biotech Industries

- 🏗️ Construction & Architecture

- 🚰 Water Treatment and Piping Systems

Advantages of Choosing SS 304 IRB Pipes & Tubes

- ✔ Lower pressure drop and improved fluid flow

- ✔ Resistance to scaling and chemical attack

- ✔ Long operational life with minimal maintenance

- ✔ Compatibility with a wide range of fluids and gases

- ✔ Aesthetic surface finish suitable for visible applications

304 vs 304L IRB Pipes – Which One to Choose?

Both grades offer similar corrosion resistance, but 304L has a lower carbon content, making it better suited for applications involving welding without post-weld annealing. Choose 304L IRB tubes when welding is a primary requirement and intergranular corrosion needs to be avoided.

Conclusion

Stainless Steel 304 IRB Pipes & Tubes provide a robust and efficient solution for industries demanding performance under pressure and in corrosive environments. Their smooth internal structure, combined with the trusted strength of SS 304, makes them the go-to choice for fluid transport and structural applications.

Whether you're in the chemical, food, or water treatment industry, using IRB tubes enhances performance, reduces downtime, and improves long-term system reliability.