PVB Glass Laminating Machine | Ervin Sales Group USA | Advanced Glass Machinery Solutions

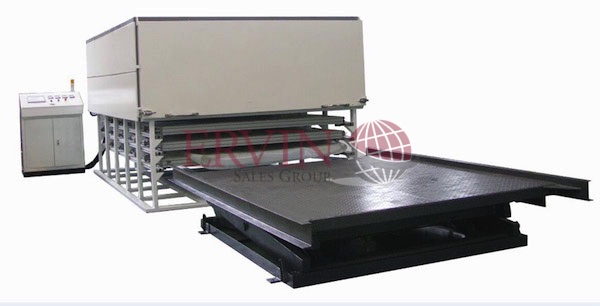

At the heart of this process lies the PVB Glass Laminating machine, a critical piece of modern glass machinery that ensures durability, clarity, and performance.

The demand for laminated glass continues to rise across industries such as architecture, automotive, aerospace, and interior design. Safety regulations, energy efficiency, sound insulation, and aesthetic appeal have made laminated glass a preferred choice worldwide. At the heart of this process lies the PVB Glass Laminating machine, a critical piece of modern glass machinery that ensures durability, clarity, and performance.

At Ervin Sales Group USA, we specialize in providing advanced, reliable, and cost-effective glass processing solutions. Our PVB Glass Laminating machine is engineered to meet the highest industry standards while integrating seamlessly with other essential equipment such as glass washing machines, glass cutting machines, and glass drilling machines.

In this blog, we’ll explore how a PVB Glass Laminating machine works, its benefits, applications, and why Ervin Sales Group USA is your trusted partner for glass manufacturing excellence.

What Is a PVB Glass Laminating Machine?

A PVB Glass Laminating machine is used to manufacture laminated glass by bonding two or more glass sheets together using a Polyvinyl Butyral (PVB) interlayer. The glass layers are fused under controlled heat and pressure, creating a strong, transparent, and impact-resistant product.

Unlike standard glass, laminated glass does not shatter upon impact. Instead, the broken fragments adhere to the PVB layer, significantly improving safety and structural integrity.

How the PVB Glass Lamination Process Works

The laminated glass production process involves multiple stages and supporting glass machinery:

1. Glass Cutting

The process begins with precision sizing using a glass cutting machine. Accurate cuts ensure proper alignment and reduce material waste.

2. Glass Washing

After cutting, the glass must be thoroughly cleaned using a glass washing machine. Dust, oil, or residue can compromise lamination quality.

3. Interlayer Assembly

A PVB interlayer is placed between the cleaned glass sheets in a controlled environment.

4. Pre-Lamination

The assembled glass passes through a pre-lamination section where air is removed and the layers are lightly bonded.

5. Autoclave or Laminating System

The PVB Glass Laminating machine applies heat and pressure to permanently bond the glass and interlayer.

6. Drilling and Finishing

Optional processing using a glass drilling machine allows for holes, fittings, or mounting hardware without compromising strength.

Key Features of Ervin Sales Group USA PVB Glass Laminating Machines

Our machines are designed to deliver superior performance and long-term reliability:

- ✅ High optical clarity and uniform bonding

- ✅ Automated temperature and pressure control

- ✅ Energy-efficient heating systems

- ✅ Compatibility with flat and curved glass

- ✅ Reduced material waste and production downtime

- ✅ Easy integration with existing glass machinery

Whether you're a small fabrication unit or a large industrial operation, our laminating systems are scalable to meet your production goals.

Benefits of Using a PVB Glass Laminating Machine

Enhanced Safety

Laminated glass minimizes injury risks during breakage, making it ideal for high-traffic areas.

Superior Sound Insulation

PVB layers absorb sound vibrations, making laminated glass perfect for commercial buildings and residential spaces.

UV Protection

The interlayer blocks up to 99% of harmful UV rays, protecting interiors and furnishings.

Structural Strength

Laminated glass adds rigidity and impact resistance compared to standard float glass.

Design Flexibility

Works seamlessly with glass cutting machines and glass drilling machines for customized designs.

Applications of Laminated Glass

The versatility of laminated glass makes it suitable for multiple industries:

- Architectural facades and curtain walls

- Automotive windshields and windows

- Skylights and glass roofs

- Balustrades and railings

- Bullet-resistant and security glass

- Soundproof partitions

Each of these applications relies on precision glass machinery working together, with the PVB Glass Laminating machine as the cornerstone.

Complete Glass Machinery Solutions from Ervin Sales Group USA

At Ervin Sales Group USA, we don’t just sell machines—we deliver complete production solutions. Alongside our PVB Glass Laminating machine, we offer:

- Glass Cutting Machine – for precise and efficient shaping

- Glass Washing Machine – ensures contamination-free lamination

- Glass Drilling Machine – supports advanced architectural designs

- Other high-performance glass machinery for fabrication and finishing

Our team helps you select the right equipment configuration to maximize productivity and ROI.

Why Choose Ervin Sales Group USA?

✔ Decades of industry experience ✔ Premium quality glass machinery ✔ Competitive pricing and financing options ✔ Installation, training, and after-sales support ✔ Customized solutions for your production needs

We understand that investing in a PVB Glass Laminating machine is a strategic decision. That’s why we provide expert guidance every step of the way.

Future Trends in Glass Laminating Technology

The glass industry continues to evolve with advancements such as:

- Smart laminated glass

- Energy-efficient production systems

- Automation and Industry 4.0 integration

- Lightweight, high-strength PVB interlayers

Ervin Sales Group USA stays ahead of these trends, ensuring our customers remain competitive in a rapidly changing market.

Frequently Asked Questions (FAQs)

1. What is the main purpose of a PVB Glass Laminating machine?

A PVB Glass Laminating machine bonds glass sheets with a PVB interlayer to create strong, safe, and durable laminated glass.

2. Can laminated glass be drilled after lamination?

Yes, with the right glass drilling machine, laminated glass can be drilled and finished without affecting its strength.

3. Why is a glass washing machine important before lamination?

A glass washing machine removes contaminants that can cause bubbles, delamination, or optical defects.

4. Is laminated glass suitable for outdoor use?

Absolutely. Laminated glass offers UV resistance, weather durability, and safety, making it ideal for exterior applications.

5. Does Ervin Sales Group USA provide complete glass machinery solutions?

Yes, we offer end-to-end solutions including glass cutting machines, glass washing machines, glass drilling machines, and laminating systems.

Call to Action – Power Your Glass Production Today

Ready to upgrade your glass manufacturing capabilities with a PVB Glass Laminating machine you can trust?

👉 Contact Ervin Sales Group USA today to discuss your requirements, request a quote, or schedule a consultation with our glass machinery experts.

Invest in precision. Invest in performance. Invest with Ervin Sales Group USA.

****

Visit: https://www.ervinsales.com/glass-machinery-products/PVB-Glass-Laminating-machine-5-Layer.html

Contact:

ERVIN, Inc. 13116 Lincoln Way #3138 Auburn, CA 95604 Ph: 9169338367 Email: sales@ervinsales.com