How Often Should You Use Track Cleaning Locomotives on HO Layouts

Running cleaning engines at steady intervals keeps your layout smooth, bright, and reliable. Using Track Cleaning Locomotive reduces power issues and helps every engine perform the way it should.

Keeping your layout running well takes steady care. Dust, oil, and tiny dirt particles can build up on rails faster than most hobbyists expect. Using Track Cleaning Locomotives is one of the simplest ways to maintain smooth electrical flow. These engines clean as they move, and they help prevent stalls, flickering lights, and power loss. Many modelers ask how often to run them, and the answer depends on your layout size, environment, and how frequently trains run. By understanding the right timing, you can keep your layout performing at its best.

Why Regular Cleaning Matters

Rails collect residue even when the layout is not in use. Airborne dust settles on the track. Wheels leave behind oil. Humidity can affect metal surfaces. Over time, these layers block electrical contact. Running a cleaning locomotive clears these issues before they grow into bigger problems. Clean rails help engines run smoother, start faster, and stay consistent across the entire layout.

General Timelines for Running Cleaning Locomotives

There is no fixed schedule for every layout, but there are helpful patterns to follow.

- If you run your layout several days a week, use a cleaning locomotive once every week.

- If you run trains only on weekends, cleaning every two weeks works well.

- For layouts that sit unused for long periods, run a cleaning locomotive before each operating session. These timelines keep the track fresh without overworking the cleaning unit.

How Layout Conditions Impact Cleaning Frequency

Every layout environment is different. Dusty rooms require more frequent cleaning. Rooms with pets or carpet can also collect more debris. Larger layouts with long track lines need more consistent cleaning because dirt hides in areas you may not check often. Smaller layouts may not need cleaning as frequently, but they still benefit from regular upkeep. Running Track Cleaning Locomotives helps catch buildup early and keeps engines from slowing down in hidden or tight spots.

Advantages of Cleaning Locomotives Over Manual Cleaning

Cleaning by hand takes time and can be difficult in tunnels, curves, and hidden sections. Cleaning locomotives reach every part of the track by simply running a loop. This saves time and reduces the need to lean over scenery or move structures. The steady cleaning action also helps remove grime that manual cleaning can miss. This creates smoother runs and protects sensitive engines from sudden power drops.

Tips to Get Better Results

- Run the cleaning locomotive at a slow and steady speed.

- Clean or replace pads when they show wear.

- Avoid using heavy cleaners unless the track has heavy buildup.

- Keep rolling stock wheels clean to reduce dirt spreading.

- Use the cleaning locomotive before long operating sessions.

These habits help maintain consistent track performance.

Summary Reflection:

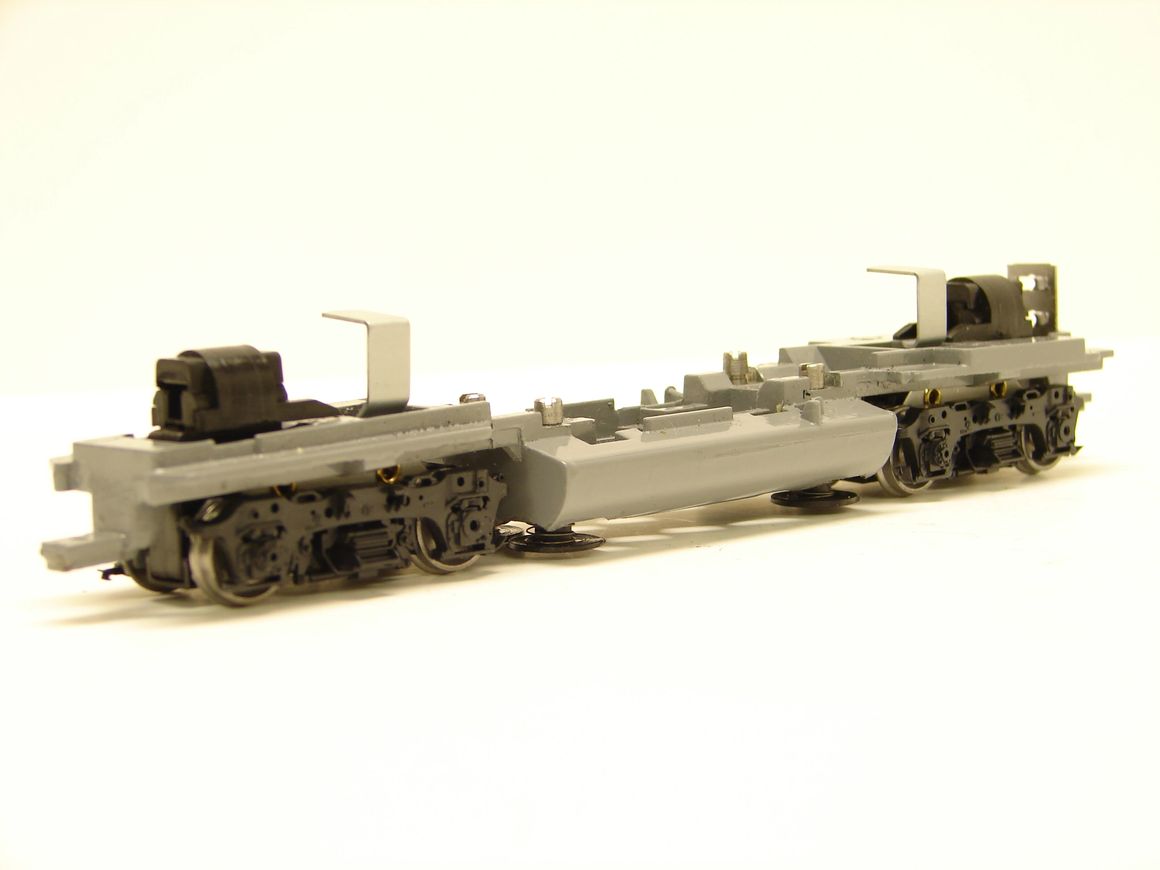

Running cleaning engines at steady intervals keeps your layout smooth, bright, and reliable. Using Track Cleaning Locomotive reduces power issues and helps every engine perform the way it should. With the right routine, even busy layouts stay clean with minimal effort. For hobbyists searching for a reliable cleaning setup or replacement parts, the Track Cleaning Locomotive Chassis Grand Rapids MI provides strong support and smooth operation for long-term use.