Flat Glass Tempering Furnace | Ervin Sales Group USA | Glass Machinery

One of the most essential technologies enabling manufacturers to meet these demands is the Flat Glass Tempering Furnace. This advanced equipment plays a vital role in producing high-strength

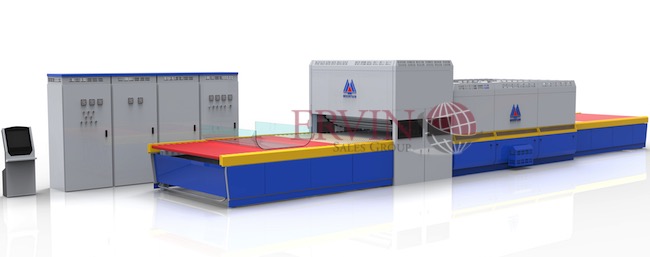

In today’s rapidly evolving glass industry, efficiency, precision, and durability are more important than ever. One of the most essential technologies enabling manufacturers to meet these demands is the Flat Glass Tempering Furnace. This advanced equipment plays a vital role in producing high-strength, safety glass used in construction, automotive, furniture, and architectural applications.

At Ervin Sales Group USA, we understand the importance of reliable and high-performance glass machinery. Whether you operate a large-scale production facility or a growing glass fabrication business, investing in a high-quality flat glass tempering furnace can significantly improve your output, quality, and profitability. In this comprehensive guide, we will explore how tempering furnaces work, their benefits, integration with other machines like the glass washing machine, glass cutting machine, and glass drilling machine, and why they are essential for modern glass processing.

Understanding the Flat Glass Tempering Furnace

A Flat Glass Tempering Furnace is a specialized industrial machine designed to strengthen glass through a controlled heating and rapid cooling process. The glass is heated to approximately 600–700°C and then quickly cooled using high-pressure air jets. This process

creates compressive stress on the glass surface, making it up to five times stronger than untreated glass.

This type of tempered glass is highly resistant to impact, thermal shock, and mechanical stress. When broken, it shatters into small, blunt fragments instead of sharp shards, making it safer for use in buildings, vehicles, and appliances. Because of these properties, tempered glass is widely used in windows, doors, facades, shower enclosures, and tabletops.

Modern tempering furnaces are equipped with advanced automation, digital temperature control, and energy-efficient systems. They ensure consistent heating and cooling, reducing defects and improving yield. When combined with other equipment such as a glass washing machine and glass cutting machine, they form a complete, streamlined glass processing line that maximizes productivity and quality.

Key Benefits of Using a Flat Glass Tempering Furnace

Investing in a flat glass tempering furnace offers numerous advantages for glass manufacturers and processors. One of the most significant benefits is enhanced strength and safety. Tempered glass is far more durable than annealed glass, making it suitable for demanding environments and regulatory requirements.

Another major benefit is improved product value. Tempered glass products command higher market prices due to their superior quality and safety features. This allows manufacturers to increase profit margins while delivering premium solutions to their customers.

Additionally, modern tempering furnaces are designed for efficiency and sustainability. Energy-saving heating systems, optimized airflow, and intelligent controls reduce operational costs. These features not only lower electricity consumption but also minimize waste and rework.

When integrated with supporting equipment like a glass washing machine for cleaning and a glass drilling machine**** for precise hole-making, the tempering furnace becomes part of a high-performance production ecosystem. This integration ensures smoother workflow, faster turnaround times, and consistent output quality.

Integration with Glass Processing Machinery

A Flat Glass Tempering Furnace does not operate in isolation. To achieve maximum efficiency, it must be integrated with complementary glass machinery. Each stage of glass processing contributes to the final product’s quality, strength, and appearance.

The process typically begins with a glass cutting machine, which shapes raw glass sheets into precise dimensions. Accurate cutting is essential because tempered glass cannot be modified after heat treatment. Any error at this stage can lead to material waste.

Next, the glass passes through a glass drilling machine, which creates holes and cutouts for fixtures, hinges, and mounting hardware. Precision drilling ensures that stress points are minimized during tempering.

Before entering the tempering furnace, the glass is thoroughly cleaned using a glass washing machine. This step removes dust, oils, and contaminants that could cause surface defects or uneven heating. A clean surface is critical for achieving flawless tempered glass.

When these machines work together seamlessly, manufacturers benefit from reduced downtime, lower rejection rates, and higher customer satisfaction. Ervin Sales Group USA specializes in providing integrated solutions that combine these technologies into efficient production systems.

Applications of Flat Glass Tempering Furnaces

The versatility of the flat glass tempering furnace makes it indispensable across multiple industries. In the construction sector, tempered glass is widely used in windows, doors, curtain walls, and skylights. Its strength and safety properties meet international building codes and standards.

In the automotive industry, tempered glass is essential for side windows, rear windshields, and sunroofs. It provides impact resistance and passenger safety while maintaining optical clarity.

The furniture and interior design sector also relies heavily on tempered glass. Tabletops, shelves, partitions, and shower enclosures require both aesthetic appeal and structural integrity. A high-quality tempering furnace ensures consistent transparency and durability.

Additionally, tempered glass is used in household appliances, electronic displays, and solar panels. As demand for smart buildings and renewable energy increases, the role of advanced glass machinery**** continues to expand. Investing in a reliable tempering furnace positions manufacturers to serve these growing markets effectively.

Choosing the Right Flat Glass Tempering Furnace

Selecting the right flat glass tempering furnace is a crucial decision that impacts production capacity, energy consumption, and long-term profitability. Several factors must be considered before making a purchase.

First, evaluate your production requirements. Consider the maximum glass size, thickness range, and daily output. Different furnaces are designed for varying capacities, and choosing the right model ensures optimal performance.

Second, focus on technology and automation. Modern furnaces with intelligent control systems offer better temperature uniformity, faster setup, and reduced human error. These features improve consistency and reduce maintenance costs.

Third, consider compatibility with existing equipment such as your glass washing machine, glass cutting machine, and glass drilling machine. A well-integrated system ensures smooth material flow and eliminates bottlenecks.

Finally, choose a reliable supplier with strong technical support and after-sales service. Ervin Sales Group USA provides industry-leading equipment, expert consultation, and comprehensive maintenance support, ensuring your investment delivers long-term value.

Why Choose Ervin Sales Group USA for Glass Machinery

Ervin Sales Group USA is a trusted provider of advanced glass machinery, including high-performance flat glass tempering furnaces. Our commitment to quality, innovation, and customer satisfaction sets us apart in the industry.

We partner with leading manufacturers to offer reliable, energy-efficient, and technologically advanced solutions. Our team works closely with clients to understand their unique production needs and recommend customized systems that maximize efficiency.

In addition to supplying tempering furnaces, we provide a full range of equipment, including glass washing machines, glass cutting machines, and glass drilling machines. This allows us to deliver complete production lines that streamline operations and reduce costs.

Our after-sales support includes installation, training, technical assistance, and spare parts availability. With Ervin Sales Group USA, you gain a long-term partner dedicated to your success in the competitive glass processing market.

Frequently Asked Questions (FAQs)

1. What is a Flat Glass Tempering Furnace used for?

A flat glass tempering furnace is used to heat and rapidly cool glass to increase its strength and safety. It produces tempered glass suitable for construction, automotive, furniture, and appliance applications.

2. Can tempered glass be cut or drilled after processing?

No, tempered glass cannot be cut or drilled after tempering. All cutting and drilling must be done beforehand using a glass cutting machine and glass drilling machine.

3. Why is a glass washing machine important before tempering?

A glass washing machine removes dust, oil, and contaminants that can cause defects during heating. Clean glass ensures uniform tempering and high-quality results.

4. How long does the tempering process take?

The tempering process typically takes a few minutes per glass sheet, depending on thickness, size, and furnace technology. Modern systems are optimized for high-speed production.

5. How do I choose the right tempering furnace for my business?

Consider production volume, glass size, automation level, energy efficiency, and compatibility with your existing glass machinery. Consulting experts like Ervin Sales Group USA can help you make the best choice.

Take Your Glass Production to the Next Level

Investing in a high-quality Flat Glass Tempering Furnace is a strategic move that enhances product quality, improves safety, and boosts profitability. When combined with advanced equipment like glass washing machines, glass cutting machines, and glass drilling machines, it creates a powerful, efficient production system.

If you are ready to upgrade your glass manufacturing capabilities, Ervin Sales Group USA is here to help.

�� Contact us today for expert consultation, customized solutions, and premium glass machinery that drives your business forward.

Let us help you transform your production line with cutting-edge technology and unmatched support.

Visit: https://www.ervinsales.com/glass-machinery-products/Flat-Bent-Glass-Tempering-Furnace.html

Contact:

ERVIN, Inc.

13116 Lincoln Way #3138

Auburn, CA 95604

Ph: 9169338367

Email: sales@ervinsales.com