Enabling Driverless Robotic Automation in Automotive Manufacturing

Minyue Technology has independent intellectual property rights of laser vision sensor software and hardware. Among them: invention patent: 2, utility model patent: 6, appearance patent: 6, software copyright: 31.

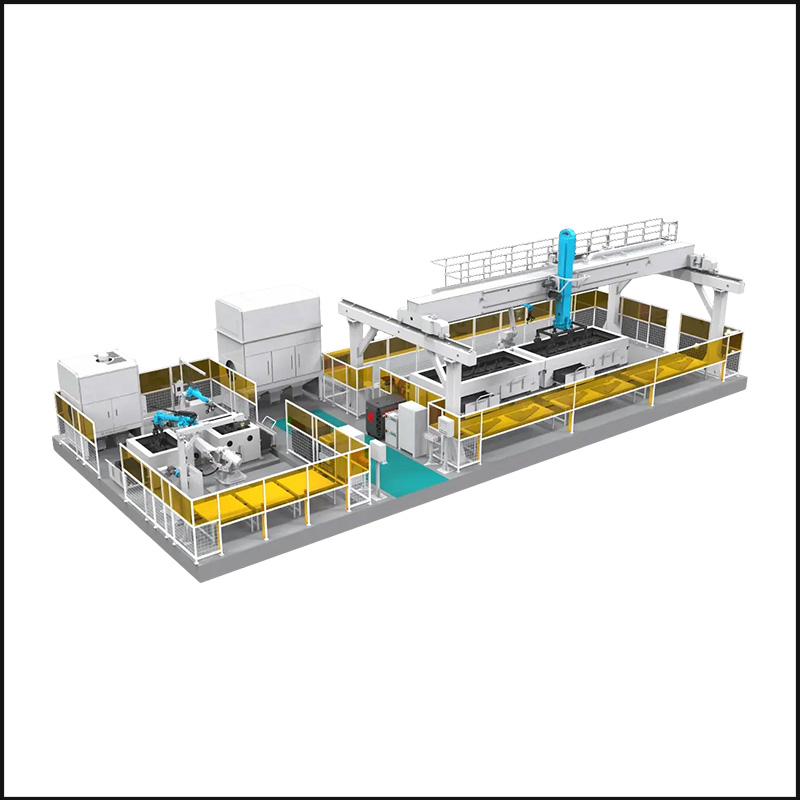

Driverless robotic automation is changing the world of car manufacturing. This new technology is helping companies like MINYUE to make cars faster, safer, and more efficiently. With driverless robots in factories, tasks that used to take a lot of time and effort can now be done quickly and easily. Imagine walking into a factory where machines take care of heavy lifting, welding, and painting without needing human help. This allows workers to focus on more important tasks, making every job smoother. As we dive deeper into how this technology is reshaping the automotive industry, we’ll see just how beneficial these robots can be.

What are the Benefits of Driverless Robotics in Automotive Production?

Using driverless robots in car making brings many advantages. First off, they do not get tired. Unlike humans, they can work around the clock without needing breaks. This means the production line can run longer, making more cars in less time. For example, a driverless robot can lift heavy car parts effortlessly, while a human would need assistance to do so safely. This leads to fewer accidents, helping keep workers safe. Moreover, robots follow specific instructions. They ensure each task is done exactly the same way every time, which means the quality of cars stays high. Mistakes are reduced, which means fewer bad cars leave the factory.

Cost savings are another big benefit. After investing in driverless technology, companies like MINYUE can save money on labor costs. Also, robots don’t require health insurance or overtime pay. In the long run, using these robots is like investing money that comes back over time. Plus, with robots, production speeds up, which means more cars can be sold more quickly.

Another point is flexibility. Robotic systems can be programmed to make different kinds of cars without much hassle. This means a factory can quickly adapt if a new car model is needed. This kind of speed helps meet changing consumer demands. All these benefits connect together, making the manufacturing process smarter and more efficient overall. We see that driverless robots are not just a trend; they are here to stay.

How Driverless Robotic Solutions Transform Manufacturing Efficiency

Driverless robotic solutions play a key role in making car manufacturing more efficient. When tasks are automated using robots, the flow of work improves. For instance, these robots work together seamlessly in teams. They can handle different aspects of car production, from assembling small parts to painting the final product. This teamwork cuts downtime. If one robot finishes its job early, it can help another robot instead of waiting around.

This leads us to the fact that machines can communicate with each other. Advanced systems allow robots to share information about their progress, letting the production line run smoothly. If one robot is delayed, others can adjust their tasks to keep the entire process moving. This smart interaction means cars are made on time and customers are happy.

Additionally, driverless robots help collect useful information. They can monitor their own performance and send updates about how fast they’re working. This helps managers like those at MINYUE to see where improvements can be made. If a robot is slower than it should be, adjustments can be made quickly to ensure efficiency is maintained. Plus, the data collected can help predict when maintenance is needed, reducing the chance of machines breaking down unexpectedly.

Alongside all these advancements, driverless robotic automation allows companies to take risks more confidently. When efficiency increases, a business can try out new designs or enter new markets without worrying too much about current operations being affected. All in all, the transformation brought by these robots is impressive, making auto manufacturing more modern and successful. Because of driverless robotics, companies like MINYUE are paving the way for the future of the automotive industry.

How to Overcome Common Challenges in Implementing Robotic Automation

Implementing robotic automation in car making can sometimes be hard. To be successful, companies like MINYUE need to be ready to face some common challenges. First, it's important to have a good plan. This plan should include choosing the right robots for the job. Different types of robots can do different tasks, so knowing what each robot can do is key. For example, some robots are good at assembling parts while others can paint cars. MINYUE should study the tasks that need to be automated and pick the robots that fit best.

Another challenge is training the workers. Some people might worry that robots will take their jobs. MINYUE can help by teaching workers how to manage and work with the robots. Training programs can show workers how robotic automation can make their jobs easier and allow them to focus on more important tasks. This way, everyone can feel safe, and teamwork between humans and robots can grow.

It's also essential to keep machines in good shape. Robots, like any other equipment, can break down or need maintenance. MINYUE should set up a regular check-up schedule to keep things running smoothly. If robots are taken care of, they can work better and last longer. Finally, a company must be patient. Changes take time. MINYUE needs to check how things are going and make changes as needed. By doing all these things, MINYUE can overcome the common challenges of robotic automation and make its car manufacturing better.

How Driverless Robotics Enhance Quality Control in Automotive Manufacturing

Driverless robots can help improve quality control in car factories. Quality control means making sure everything is made well and works as it should. MINYUE uses driverless robots to look at every single part of the car very carefully. These robots are equipped with special cameras and sensors that can see things that the human eye might miss. For example, they can find tiny scratches or painting errors on the car's surface. By using driverless robots, MINYUE ensures that all cars meet high standards before they go to customers.

In addition, these robots can work without breaks. They can do their tasks over and over again without getting tired. This means the quality control checks can be done faster, and MINYUE can catch problems early. When an issue is found, the company can fix it right away, preventing bad parts from going into the final cars. This is important because a well-made car helps customers feel safe and happy.

Moreover, driverless robotics can gather data about the quality of parts and processes. This data helps MINYUE see patterns and improve future production. For example, if many cars have a similar problem, MINYUE can look back to find out why. This way, they can change the process or fix the machines to stop the problem from happening again. Overall, driverless robots help MINYUE keep its cars high-quality and make sure customers trust their products.

What Are the Cost Savings of Integrating Driverless Automation?

Integrating driverless automation welding robot into car making can save a lot of money for companies like MINYUE. At first, it might seem expensive to buy robots and set everything up. However, in the long run, the savings can be huge. First, driverless robots work quickly and efficiently. They can produce more cars in less time than humans alone. This means MINYUE can sell more cars and, ultimately, earn more money.

Another way to save money is by reducing mistakes. When humans work, sometimes mistakes happen, like putting parts in the wrong place or not painting a car evenly. If mistakes occur, it costs money to fix robo welder them. With driverless robots, the chances of making mistakes are lower. This leads to fewer defective cars, saving money on repairs and ensuring customers are happier.

Also, driverless robots can keep working day and night. Unlike humans, they do not need breaks, which means they can produce continuously. This kind of productivity means MINYUE can keep costs low and maintain steady production schedules. Additionally, by improving productivity and quality, MINYUE can lower the cost of each car they produce. This robotic welding arm can give them a competitive edge in the market, helping them attract more customers and grow as a company.

while there may be initial costs in implementing driverless automation, the savings in time, reduced mistakes, and increased productivity lead to a brighter future. Companies like MINYUE will find that these robots not only help save money, but they also help in building better cars and satisfying their customers.