Copper Coated vs. Atomized Iron Powder: Which One Fits Your Application?

Copper Coated vs. Atomized Iron Powder: Which One Fits Your Application?

When it comes to selecting the right iron powder for industrial or manufacturing needs, two popular types often come into consideration: Copper Coated Iron Powder and Atomized Iron Powder. Each offers unique properties tailored to specific applications, and understanding their differences can help you make the best choice for your project. This article breaks down the key characteristics, advantages, and typical uses of copper coated and atomized iron powders to help you decide which one fits your application.

What is Copper Coated Iron Powder?

Copper Coated Iron Powder consists of iron particles with a thin layer of copper plating. This copper coating enhances the powder’s surface conductivity and corrosion resistance, making it especially valuable in applications that require electrical conductivity or improved bonding properties. The copper layer also prevents the iron from oxidizing prematurely, improving shelf life and performance consistency.

This type of iron powder is commonly used in the welding industry, particularly in electrode manufacturing, where stable arcs and strong joints are essential. Additionally, copper coated iron powder is favored in magnetic materials and conductive composites, as the copper surface facilitates better electrical and thermal conductivity.

What is Atomized Iron Powder?

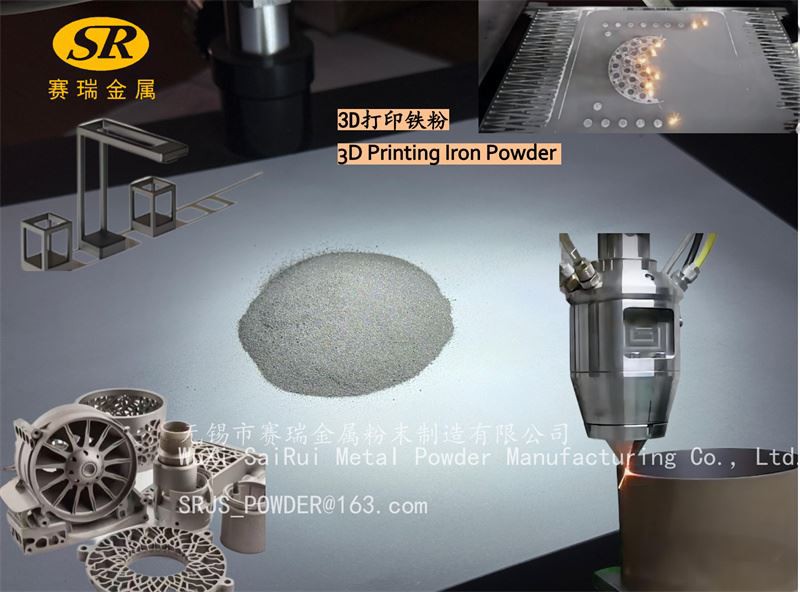

Atomized Iron Powder is produced by spraying molten iron through a high-pressure gas or water stream, rapidly cooling it into fine, spherical particles. The atomization process yields iron powder with excellent flowability, uniform particle size, and high purity. This makes Atomized Iron Powder highly versatile for powder metallurgy, where it is compacted and sintered to create dense, durable metal parts.

Typical uses of atomized iron powder include automotive components like gears and shafts, industrial machinery parts, and magnetic cores. Its spherical shape enhances packing density and mechanical properties, making it ideal for precision engineering and manufacturing.

Key Differences Between Copper Coated and Atomized Iron Powder

- Surface Treatment: Copper coated iron powder features a copper layer enhancing conductivity and corrosion resistance, whereas atomized iron powder is generally untreated and valued for particle uniformity.

- Particle Shape: Atomized powder is typically spherical, promoting better flow and compaction, while copper coated powder particles may have irregular shapes depending on the base iron powder.

- Applications: Copper coated iron powder excels in electrical and welding applications; atomized iron powder is preferred for structural parts and components made via powder metallurgy.

- Cost: Copper coating adds to production costs, making copper coated iron powder generally more expensive than atomized iron powder.

- Performance: Copper coated powder offers better conductivity and resistance to oxidation; atomized powder provides superior packing density and mechanical strength.

Which One Fits Your Application?

Choosing between copper coated and atomized iron powder depends primarily on your end-use requirements:

- If your application demands high electrical conductivity, corrosion resistance, and improved bonding — such as in welding electrodes or conductive composites — Copper Coated Iron Powder is the better choice.

- If your focus is on mechanical strength, density, and precision shaping for parts like gears, bearings, or automotive components made through powder metallurgy, then Atomized Iron Powder will better suit your needs.

Conclusion

Both copper coated and atomized iron powders serve critical roles in industry, but their distinct properties make them suitable for different applications. Understanding your specific requirements — whether electrical performance, mechanical strength, or manufacturing process compatibility — will guide you toward the right iron powder. Whether you need the enhanced conductivity of copper coated powder or the uniformity and flowability of atomized powder, selecting the appropriate material ensures optimal results and efficiency in your production process.