Bellows Seal Control Valve: Ensuring Precision and Safety in Fluid Control

Bellows Seal Control Valve: Ensuring Precision and Safety in Fluid Control

Introduction In industries where safety, reliability, and leak-free operation are paramount, bellows sealed control valves offer a sophisticated solution. Designed to handle toxic, hazardous, or high-value fluids, these valves ensure absolute containment and performance in demanding applications. This article explores the engineering, applications, and advantages of bellows sealed control valves, demonstrating why they are increasingly the valve of choice across a wide range of industries.

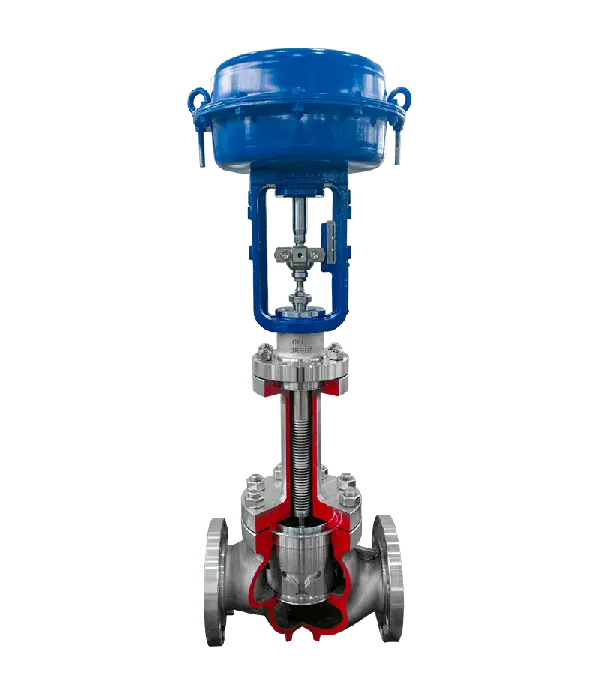

What Is a Bellows Sealed China Control Valve? A bellows sealed control valve is engineered to deliver a hermetic, zero-leakage seal around the valve stem using a metallic bellows element. This bellows—typically fabricated from corrosion-resistant alloys such as stainless steel—is welded to both the valve stem and the bonnet, completely isolating the process media from the atmosphere.

The core function of the bellows is to eliminate fugitive emissions, making the valve ideal for controlling dangerous or valuable substances while upholding environmental and safety standards.

Key Design Features

- Metallic Bellows Assembly The internal stainless-steel bellows enables leak-free stem motion, withstanding thermal expansion, pressure cycling, and aggressive fluids.

- Top-Guided, Unbalanced Design Built for durability, this configuration supports heavy-duty applications while maintaining high control precision.

- S-Type Flow Path The contoured flow channel reduces pressure drop and turbulence, ensuring efficient fluid dynamics and better process control.

- Double Sealing Mechanism A secondary packing seal complements the bellows, providing redundant containment and added operational safety.

- Press-In Seat Cage Design This innovative approach improves serviceability by eliminating the downsides of screw-in seats, such as high leakage and complex maintenance.

- Flow-to-Open Configuration The valve’s flow direction supports precise modulation and ensures stable performance in small openings—critical for fine control.

- Optional Noise and Cavitation Control Custom-engineered cages are available to suppress noise and prevent cavitation in high-pressure applications, extending the valve’s life.

Applications of Bellows Sealed Control Valves

These valves are trusted across industries where precision, purity, and safety are essential:

- Chemical Processing Ideal for corrosive and toxic media, these valves offer safe and reliable control without leakage risks.

- Oil & Gas In high-pressure and high-temperature environments, bellows valves ensure robust sealing performance in upstream and downstream applications.

- Pharmaceuticals Designed to prevent contamination, bellows valves maintain product purity throughout sensitive manufacturing processes.

- Power Generation Used to regulate steam, cooling water, and feedwater, these valves play a critical role in plant efficiency and operational safety.

- Food & Beverage Offering hygienic, contamination-free control, bellows sealed valves help meet strict sanitation standards.

- Semiconductor Manufacturing Ultra-clean operation is a necessity in chip production—bellows valves prevent even microscopic leaks that could compromise yields.

Advantages of Bellows Sealed Control Valves

- Zero Emissions Compliance The hermetically sealed bellows eliminate the risk of environmental leakage—key for meeting stringent global emission regulations.

- Extended Service Life Built with high-grade metals and a wear-resistant design, these valves offer exceptional durability, even in harsh service conditions.

- Operational Safety Leak prevention ensures safe operation for personnel and surrounding equipment, especially with hazardous or explosive media.

- Precision Fluid Control The guided stem design and flow-to-open mechanics support highly accurate modulation, crucial in process-sensitive industries.

- Versatility in Harsh Conditions Available with various trims, seat materials, and bellows designs, these valves adapt to noise-prone, cavitating, or high-pressure systems.

- Reduced Maintenance and Downtime The rugged design minimizes mechanical wear and maintenance frequency, lowering operating costs and boosting productivity.

- Regulatory Compliance These valves are often certified or manufactured to comply with standards like API, ASME, DIN, and ISO for critical process control.

Conclusion Bellows sealed control valves are a breakthrough in valve engineering, offering unmatched sealing integrity, safety, and performance. Their ability to operate reliably in hazardous, high-pressure, or ultra-pure environments makes them essential in modern industrial systems.

From chemical processing and pharmaceuticals to semiconductors and energy, these valves not only protect workers and the environment but also deliver consistent, long-term value. As global industries prioritize environmental safety and precision control, the bellows sealed control valve stands as a benchmark for advanced fluid handling technology.

In essence, these valves aren’t just components—they’re mission-critical solutions for modern industry, setting the standard for safety, efficiency, and control.Know more about Google SEO Directory