Automotive Metal Stamping Market Insights By Process Type And Regional Growth

The automotive metal stamping market is poised for steady growth, supported by rising vehicle production, technological advancements in stamping processes, and the increasing adoption of lightweight materials in vehicle manufacturing.

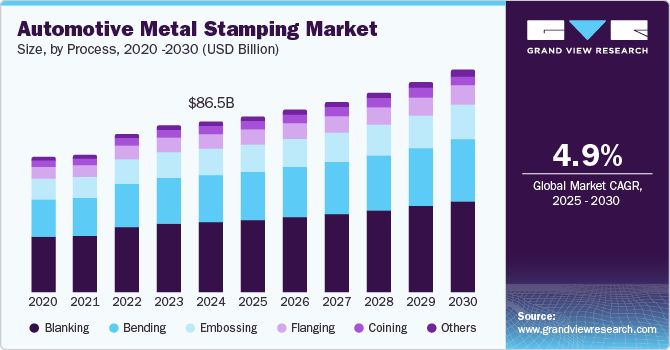

The global automotive metal stamping market was valued at USD 86.5 billion in 2024 and is projected to reach USD 113.2 billion by 2030, growing at a CAGR of 4.9% from 2025 to 2030. Market expansion is driven by increasing vehicle production and rising demand for passenger cars worldwide.

Advancements in manufacturing technologies, such as laser and hydraulic stamping, are enhancing production efficiency, reducing costs, and improving precision, further fueling market growth. The growing adoption of electric vehicles (EVs) also supports demand for specialized stamped components, including battery enclosures and lightweight structural parts, reflecting the evolving needs of the automotive industry.

Additionally, the trend toward engine downsizing to improve fuel efficiency has increased the demand for lightweight metals like aluminum, which are extensively utilized in metal stamping processes. The expansion of manufacturing facilities and strategic contracts between key original equipment manufacturers (OEMs) and automotive stamping companies also contribute to the market’s growth trajectory.

Key Market Trends & Insights

- Asia Pacific dominated the automotive metal stamping market, accounting for 40.8% of global revenue in 2024.

- By process, the blanking segment led the market with a 39.3% share in 2024.

- By application, the passenger car segment held the largest market share in 2024.

Download a free sample PDF of the Automotive Metal Stamping Market Intelligence Study by Grand View Research.

Market Size & Forecast

- 2024 Market Size: USD 86.5 Billion

- 2030 Projected Market Size: USD 113.2 Billion

- CAGR (2025–2030): 4.9%

- Asia Pacific: Largest regional market in 2024

Competitive Landscape

Key players in the automotive metal stamping market are leveraging technological innovation, strategic partnerships, and capacity expansions to strengthen their market presence.

- American Industrial Co. specializes in metal stamping for automotive applications, offering cost-effective solutions for components such as fenders and hub caps. Their processes utilize a range of metals, including steel and aluminum, for high-volume production runs.

- D&H Industries, Inc. provides precision metal stamping services for automotive components, including body panels, chassis parts, and structural elements.

Prominent Companies

- AAPICO Hitech Public Company Limited

- American Industrial Co.

- CAPARO

- D&H Industries, Inc.

- FCA

- Ford Motor Company

- General Motors

- Gestamp

- Goshen Stamping Company

- Kenmode, Inc.

- Nissan Motor Co., Ltd.

- Tempco Manufacturing Company, Inc.

Explore Horizon Databook – the world’s most comprehensive market intelligence platform by Grand View Research.

Conclusion

The automotive metal stamping market is poised for steady growth, supported by rising vehicle production, technological advancements in stamping processes, and the increasing adoption of lightweight materials in vehicle manufacturing. The expanding demand for EV components and passenger car parts will continue to drive the need for efficient and precise metal stamping solutions globally.