A Bellows Seal Valve: Your Ultimate Defense Against Industrial Leakage

A bellows seal valve is a type of industrial valve designed to provide a completely leak-proof, or "hermetic," seal around the valve stem.

In the world of industrial operations, a tiny leak can have catastrophic consequences. From lost profits and decreased efficiency to severe environmental damage and fatal accidents, the risks are immense. The recent tragic nitrogen gas leak at a pharmaceutical company in Palghar, Maharashtra, which claimed four lives, is a stark and painful reminder of the critical need for a zero-leakage policy in industries handling hazardous substances. While the exact cause of the Palghar incident is still under investigation, it highlights a crucial vulnerability in industrial systems: the potential for valve failures. This is where the bellows seal valve emerges as a game-changing solution, offering an unparalleled level of safety and reliability.

The Silent Threat: Conventional Valve Leakage

Traditional valves, particularly those that rely on a packing gland to seal the stem, are prone to a phenomenon known as "fugitive emissions." This refers to the unintentional release of gases or vapors into the atmosphere from industrial equipment. The packing material, which is often made of graphite or PTFE, is designed to compress around the valve stem to prevent leaks. However, this packing can degrade over time due to wear, thermal cycling, and pressure fluctuations. This degradation creates microscopic pathways for fluids or gases to escape, leading to small, continuous leaks that can go unnoticed but accumulate into significant safety hazards and financial losses.

In industries dealing with highly volatile, toxic, or valuable media, even a minor leak can result in immense danger, environmental fines, and product waste. A conventional valve's reliance on a material that wears out makes it a ticking time bomb for potential failures, underscoring the need for a more robust and dependable sealing mechanism.

Bellows Seal Valves: The Zero-Leakage Solution

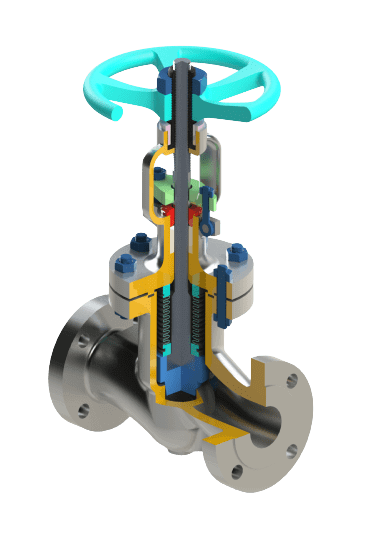

Unlike conventional valves, a Bellows seal valve is engineered to provide a hermetically sealed barrier against leakage. Its core innovation lies in a flexible, accordion-like metal component—the bellows—that is welded to both the valve stem and the valve bonnet. This design creates a permanent, impenetrable metal barrier, completely isolating the process fluid from the atmosphere.

As the valve opens and closes, the bellows expands and contracts, allowing for seamless stem movement without compromising the seal. This ingenious design eliminates the need for traditional packing and, with it, the risk of fugitive emissions. The bellows seal valve is built for longevity and durability, providing a maintenance-free sealing solution that drastically reduces the total cost of ownership over its lifespan.

Key Advantages of Bellows Seal Valves

Beyond their zero-leakage capability, bellows seal valves offer a multitude of benefits that address critical industry pain points:

- Enhanced Safety and Environmental Compliance: By preventing the escape of hazardous and toxic materials, bellows seal valves are instrumental in improving workplace safety and meeting stringent environmental regulations. This is particularly vital in sectors like chemical processing, nuclear power, and pharmaceuticals where the stakes are incredibly high.

- Cost Savings and Energy Efficiency: Leaks, even minor ones, can lead to substantial product loss and wasted energy, especially in steam systems. The hermetic seal of a bellows valve prevents this waste, directly contributing to lower operational costs and a more energy-efficient plant. Over time, the savings on lost product and maintenance can easily outweigh the initial investment.

- Reduced Maintenance and Downtime: The wear-and-tear of packing in conventional valves requires frequent, costly maintenance and can lead to unplanned shutdowns. Bellows seal valves eliminate this need, as the durable metal bellows are designed for a long service life, ensuring continuous operation and maximizing plant uptime.

- Robust Performance in Extreme Conditions: Bellows seal valves are built to withstand a wide range of operating conditions, including high temperatures and pressures. Their robust construction and reliable sealing mechanism ensure stable performance even in the most demanding environments, a critical factor for industries where process integrity is non-negotiable.