5 Spindle Glass Edging Machine | Ervin Sales Group USA | Glass Machinery

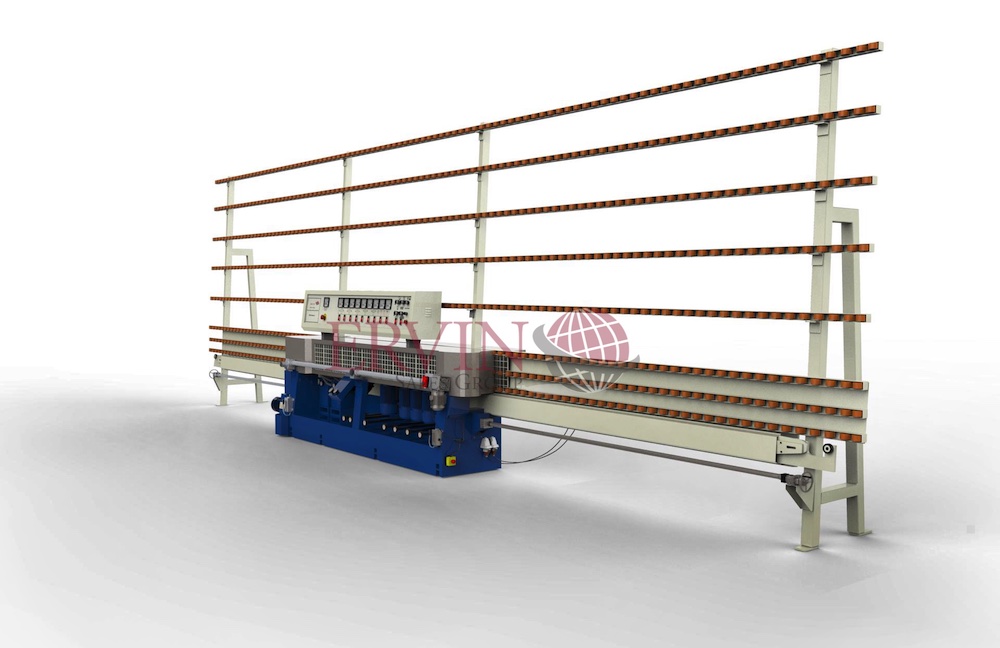

If you’re looking to streamline your glass production line, the 5 Spindle Glass Edging Machine is an ideal choice for workshops and industrial manufacturers alike.

In today’s competitive glass processing industry, precision, efficiency, and durability are essential. One machine that continues to be a backbone of modern glass fabrication is the Spindle Glass Edging Machine. At Ervin Sales Group USA, we provide advanced glass machinery solutions designed to improve productivity, reduce waste, and deliver superior finishing quality.

If you’re looking to streamline your glass production line, the 5 Spindle Glass Edging Machine is an ideal choice for workshops and industrial manufacturers alike.

What Is a 5 Spindle Glass Edging Machine?

A 5 Spindle Glass Edging Machine is a high-performance glass processing machine used to grind, polish, and edge glass panels with accuracy and consistency. Each spindle performs a specific operation—rough grinding, fine grinding, and polishing—ensuring a smooth, professional finish on glass edges.

This machine is commonly used alongside other essential equipment such as a glass washing machine, glass drilling machine, and glass cutting machine, forming a complete glass processing solution.

Key Benefits of a Spindle Glass Edging Machine

✔ Precision Edge Finishing

The Spindle Glass Edging Machine delivers clean, uniform edges that meet architectural and industrial standards.

✔ High Productivity

With five spindles operating sequentially, production time is reduced while maintaining exceptional quality.

✔ Versatile Glass Applications

Suitable for flat glass, tempered glass, and laminated glass used in furniture, windows, doors, and commercial projects.

✔ Seamless Integration

Easily integrates with a glass cutting machine for shaping, a glass drilling machine for holes, and a glass washing machine for final cleaning.

✔ Durable & Cost-Effective

Built for long-term industrial use, this machine minimizes maintenance costs and maximizes ROI.

Why Choose Ervin Sales Group USA for Glass Machinery?

At Ervin Sales Group USA, we specialize in reliable, high-quality glass machinery tailored to your production needs. Our equipment is sourced from trusted manufacturers and supported by expert technical guidance.

Whether you’re upgrading your facility or starting a new glass fabrication line, our solutions help you stay competitive with cutting-edge technology.

Complete Glass Processing Line Solutions

For maximum efficiency, the 5 Spindle Glass Edging Machine works best when paired with:

- Glass Cutting Machine – Accurate shaping and sizing

- Glass Drilling Machine – Clean and precise holes

- Glass Washing Machine – Spotless, residue-free glass

Together, these machines create a streamlined workflow that enhances output and product quality.

Frequently Asked Questions (FAQs)

1. What is a Spindle Glass Edging Machine used for?

A Spindle Glass Edging Machine is used to grind, polish, and finish the edges of glass panels for safety and aesthetics.

2. Why choose a 5 Spindle Glass Edging Machine?

The 5 Spindle Glass Edging Machine offers a balance of speed, precision, and affordability, making it ideal for small to medium-scale glass manufacturers.

3. Can this machine work with other glass machinery?

Yes, it integrates seamlessly with a glass cutting machine, glass drilling machine, and glass washing machine for a complete production line.

4. What industries use glass edging machines?

They are widely used in architectural glass, furniture manufacturing, automotive glass, and interior design industries.

5. Does Ervin Sales Group USA provide support and service?

Absolutely. Ervin Sales Group USA offers expert consultation, technical support, and dependable after-sales service.

Call to Action

🚀 Upgrade your glass production today! Discover how the 5 Spindle Glass Edging Machine from Ervin Sales Group USA can improve efficiency, quality, and profitability.

👉 Contact Ervin Sales Group USA now to request a quote, schedule a consultation, or explore our full range of glass machinery, including glass cutting machines, glass drilling machines, and glass washing machines.

Visit: https://www.ervinsales.com/glass-machinery-products/5-Spindle-Glass-Edging-Machine.html

Contact:

ERVIN, Inc. 13116 Lincoln Way #3138 Auburn, CA 95604 Ph: 9169338367 Email: sales@ervinsales.com